White paper Supply Chain Network Management

Boosting Robustness, Resilience and Responsiveness

What does the stable supply chain network of tomorrow look like? Those who come out on top will be supply chain networks that at their core have three capabilities: Robustness, responsiveness and resilience.

All reconfiguration measures are geared towards strengthening these three capabilities. Companies then benefit from the fact that a robust network has suitable measures in place to protect them against events with a lower severity and enables continuous operation. The more responsive the network is, the quicker the company is capable of making suitable adjustments and to continue with the performance.

Christian Ullrich

PrincipalSTAUFEN.AG

After his master studies in Industrial Engineering and Management at Karlsruhe Institute of Technology, he gained 4.5 years of consulting experience in supporting companies on their way to Lean Transformation. Furthermore he has international project experience in other European countries and experienced the management of projects for medium-sized customers and takeover of sub-projects for corporate groups. In reference projects he knows about the holistic OEE improvements in plant-intensive industries, introduction of Shop Floor Management, as well as coaching of executives in Shop Floor Management from team leader to managing director. Furthermore the introduction of a synchronized stand assembly incl. logistics connection in plant construction and factory planning projects (brownfield and greenfield). Complementary the design of cross-plant value streams and the optimization and design of assembly lines incl. connection to logistics.

Read moreWhat does the stable supply chain network of tomorrow look like?

The white paper illustrates the future challenges and requirements of the value creation network, addresses specific dimensions of successful supply chain network management, explains the need for a risk management and shows how companies can achieve a successful network in 5 steps.

In the past, the goals were almost exclusively the classic “competitive priorities” – costs, time, flexibility, quality and innovation. Now, robustness and resilience are at the top of the list.

Prof. Dr. Thomas Friedli

University of St. Gallen (HSG), Institute for Production Management

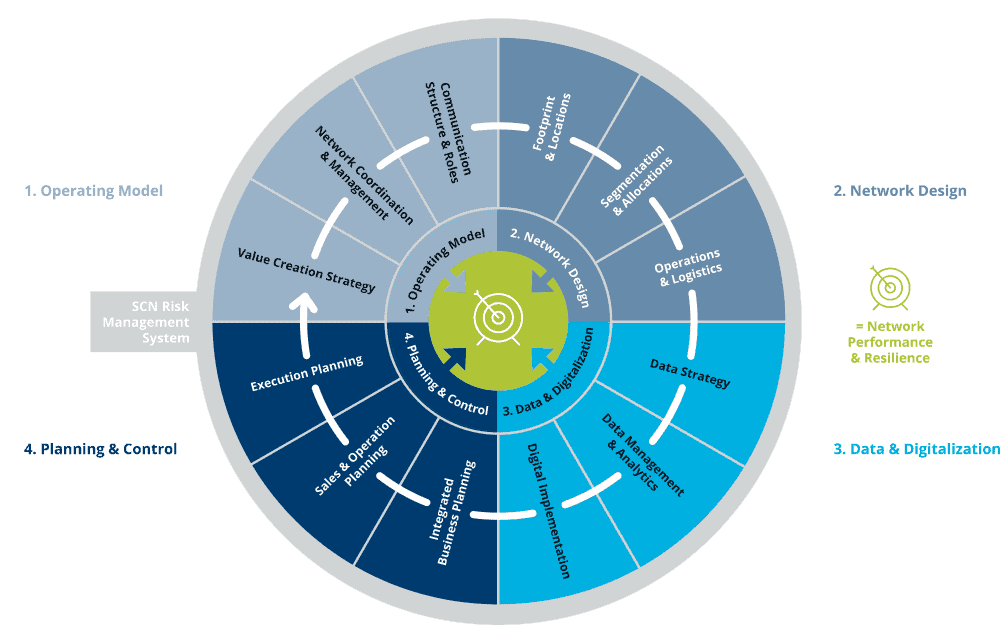

Supply Chain Network Management Framework

This is why the Staufen supply chain network management approach focuses on the dimensions of robustness, responsiveness, and resilience alongside the classic performance criteria, showing how the loss zone can be kept to a minimum and a rapid return to a normalized performance level can be achieved.

All terms and explanations of our SCNM framework can be found in our SCNM glossary.

Key Lessons

- The current supply chain shortages will continue to affect the economy for some time to come and will continue to cause delays throughout the value creation networks and cost increases in the industry.

- Companies need to respond more quickly to disruptions in the network and in raw material and energy supplies if they are to be better equipped to meet future challenges.

- Classic supply chain management is not sufficiently equipped to manage increasingly complex networks and ensure transparency along all processes and resources on all levels.

- State-of-the-art supply chain network management improves network performance by helping to align the individual segments across functions.

- Introducing a supply chain risk management ensures the ability to detect potential risks early and to strengthen network resilience.

- A well performing network helps companies to increase their competitive advantage.

Would you like to learn more? Request the white paper now free of charge!

Your Experts for Supply Chain Network Management

Do you want your company to be able to be robust, resilient and respond quickly to increasingly new requirements? Our consultants look forward to speaking with you in person and working with you!

Christian Ullrich

PrincipalSTAUFEN.AG

After his master studies in Industrial Engineering and Management at Karlsruhe Institute of Technology, he gained 4.5 years of consulting experience in supporting companies on their way to Lean Transformation. Furthermore he has international project experience in other European countries and experienced the management of projects for medium-sized customers and takeover of sub-projects for corporate groups. In reference projects he knows about the holistic OEE improvements in plant-intensive industries, introduction of Shop Floor Management, as well as coaching of executives in Shop Floor Management from team leader to managing director. Furthermore the introduction of a synchronized stand assembly incl. logistics connection in plant construction and factory planning projects (brownfield and greenfield). Complementary the design of cross-plant value streams and the optimization and design of assembly lines incl. connection to logistics.

Read moreREQUEST THE WHITE PAPER NOW AS A DIGITAL VERSION