Kata Training

Consistent competence in improvement and leadership

Kata is a term that comes from martial arts: the act of constantly practicing and applying a sequence of actions is designed to turn it into a routine which can be called up instantly as needed. Mike Rother makes a distinction between improvement kata and coaching kata. In improvement kata, the objective is to apply a learning routine to the process of gradually achieving a defined target.

Improvement kata is based on an interaction between the student (usually an employee) and the coach (usually a manager). Correctly applying improvement kata is supported by coaching kata.

In our two-phase training program, you will learn about improvement kata and coaching kata and learn how to apply them. You will then be able to try out kata and use it independently in your company.

The key effects of this approach: Accelerating or revitalizing your CIP, increasing the adaptability of your company, engaging in strategic continuing development of the employees and managers involved, creating happiness, and experiencing many “Eureka!” moments in jointly applying these techniques as well as rapidly achieving sophisticated goals.

Your advantages

The concept of a learning organization is nothing new – but it has never been as relevant as it is today! In times of great changes and constant fluctuation, one of the most important factors to help you stand out from the competition is adaptability as well as the capability of learning steadily and in short cycles. Ultimately, of course, it is not the organizations that learn: it’s the employees. The 70-20-10 model of learning states that nearly 90% of learning takes place by means of professional challenges, stimulating tasks and an exchange of ideas at the workplace. And managers have a significant effect on creating learning situations. There is hardly any method that is more suitable here than Kata: its daily routines and structured exchange between managers and employees help achieve a specifically defined target. And in the process, both parties experience long-term learning: the employee and the manager alike!

Kaizen and CIP workshops and projects are absolutely justified, especially at the outset of a company’s Lean transformation or when they are implementing major changes. Here people explore methods, create lighthouses and generate remarkable results on a hands-on basis. Usually these outcomes are achieved by Lean experts (in-house and / or external). One problem here is that these workshops are event-related, which means that in a best-case scenario, they take place only in the appropriate areas and departments. At the same time, however, daily business cannot suffer as a result, and the experts themselves are resources in high demand. Kata is an excellent complement and jumping-off point in these situations, since ideally it can be used every day and requires little, if any, input from experts. As a result, CIP is put into practice on a daily basis across all areas as it is being implemented.

Creating learning organizations and experiencing dynamic DIP

By applying Kata

In our two-phase training program, you will learn about improvement kata, coaching kata and learn how to apply them. You will then be able to try out kata and use it independently in your company.

This training program is available as an in-house solution. Contact us now for a nonbinding quote:

Is this training for you?

Margret Messerle

Specialist Academy Organisation

STAUFEN.AG

Phone: '+49 7024 8056 188

E-Mail: academy-service@staufen.ag

READ MORE

“Thanks to Shop Floor Management, we have really taken off with the Lean Transformation.”

To take full effect, a Lean Transformation must include all levels of a company. This is like running a marathon, explain Alexander Burgbacher and Stephan Filthuth in the podcast. Insta GmbH, which they lead, has not yet completed its first marathon, but it’s already clear: there will be a second one.

Read more

“We put the horsepower on the street with kata.“

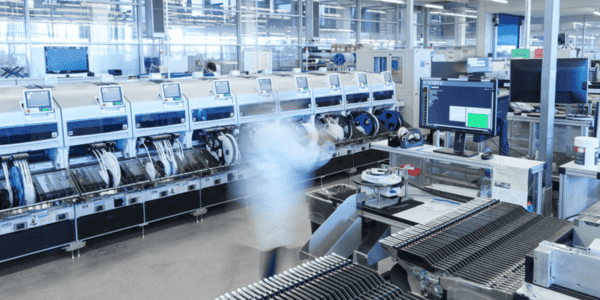

The electronics specialist Insta has set out on the path to becoming a learning organization. To achieve its goal, this company in the Sauerland is relying especially on coaching of the employees. The principle of constant improvement should ensure on all teams that new requirements are implemented more quickly.

Read more

Communication, focus and commitment

In the plastics processing industry, too, the trend toward individualization is creating increasingly complex process landscapes. The machine manufacturer Arburg is responding to this with a comprehensive organizational change.

Read more