The green transformation determines our future economic activity

The manufacturing industry has a responsibility to reduce its environmental footprint. Legal requirements and growing social pressure have set a process of rethinking in motion: corporate leaders see a need to reassess the environmental impact of their work.

For many companies, the economic viability of ecological measures is still a major challenge. However, they also recognize the opportunity to improve their own competitiveness in terms of productivity, costs and quality through sustainable transformation.

OUR EXPERTISE? GO GREEN.

As the best Lean Management consultancy in Germany, we know how to optimize processes, prevent waste and change value creation systems in a holistic and sustainable manner. We analyze existing value creation processes, identify sustainability potential and work with you to implement needs-based solutions for your CO₂ targets.

STRATEGY AND ROADMAP

In order to follow a clear target image from the start, it is important to get an overview of the existing sustainability management. Which processes, structures and responsibilities are used to anchor the topic in the organization? Which fields of action have already been defined? We support you in defining your sustainability strategy and in selecting and reviewing effective measures.

Supply chains are increasingly developing into multidimensional, complex and global value chains. Mastering sustainable value chains is therefore becoming one of the greatest challenges for corporate sustainability performance. The sustainable supply chain approach from Staufen supports companies from strategy to implementation and helps sustainably align the entire network with future requirements and confidently control it with transparent management systems.

Preventing waste in operational processes is part of our core business and offers great potential for the reduction of raw materials and energy. We support you in expanding a resource-optimized value creation system and ensure best-of-class results in your production.

Sustainable companies need new leadership methods and competencies.

After all, managers who act sustainably today not only have an economic responsibility, but also a social and ecological one. They act as role models and should enable their employees to think and act sustainably. A company has a sustainable corporate culture only if there is a shared understanding among a sustainably acting organization at all levels.

Our change management approach enables companies to establish leadership methods, organizational structures and systemic processes that make them more sustainable and thus more fit for the future.

Process mining involves mining the data streams of corporate networks. The aim is to leverage unused potential or prevent waste. This method can also be used to achieve greater transparency in the area of sustainability. With the help of the Execution Management System (EMS) from our digital partner Celonis, we can screen companies, identify problems and quickly derive recommendations for action thanks to AI.

In contrast to classic transaction systems, Celonis links the processes and offers a complete view, from raw materials to logistics, and production to delivery.

Depending on the case, more than just the classic economic factors are examined. Sustainability factors can also be filtered out: risk mapping, emissions, social standards, etc. Once all the data has been compiled, the sustainability of the entire value chain can be determined.

Our partner in the area of sustainability

Combined expertise on lean processes and C02 footprint: Staufen AG and Fokus Zukunft GmbH & Co. KG will work together in the future on the topic of sustainability. Together, we will support companies along their entire path to climate neutrality.

SUSTAINABILITY QUICK-CHECK

Our Quick-Check offers focused, sound results and instructions for action that companies can use to prioritize and optimize sustainability measures. We conduct the Quick-Check in cooperation with Fokus Zukunft, our partner for sustainability strategies.

HOW DO YOU BECOME A CO₂-NEUTRAL COMPANY?

General energy savings and a CO₂-neutral energy supply are currently the most important ecological goals for many companies. This is not just about in-house production; emissions from the upstream supply chain must also be taken into account.

Corporate Carbon Footprint

What emissions does an organization produce in a given period of time (end-to-end process)?

Product Carbon Footprint

What emissions does a product cause in product lifecycle/value chain “cradle-to-grave” or “cradle-to-ramp”?

Project Carbon Footprint

What emissions does a particular project produce for a particular period of time?

HOW IS THE CO₂ FOOTPRINT MEASURED?

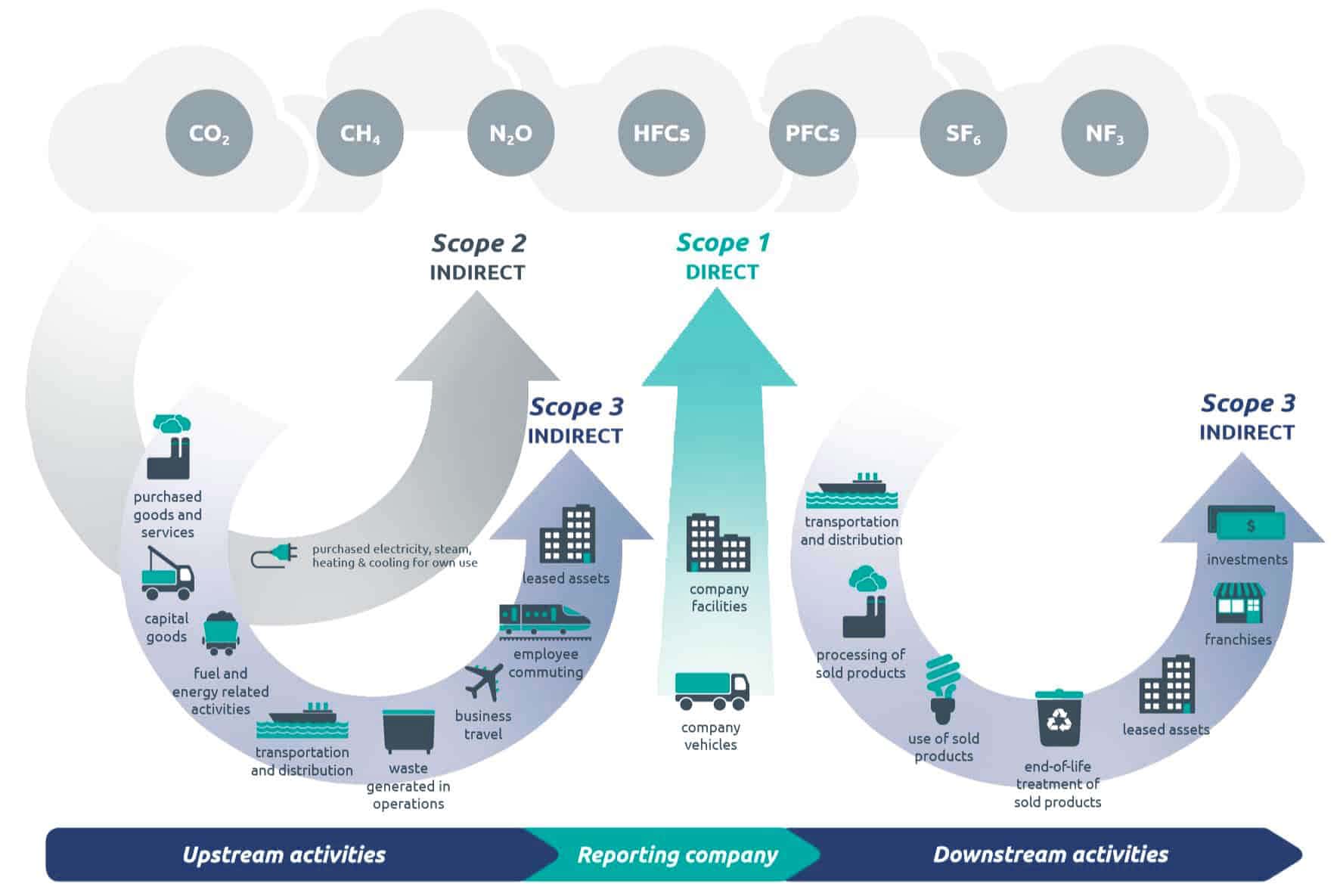

The CO₂ footprint can be measured along the value chain according to its contribution to the emission of CO₂ equivalents.

Direct emissions within the company’s operations and internal power generation

Indirect emissions from external electricity generation for Group operations

All indirect emissions caused by the company; includes emissions within the supply chain of products and services, employee travel and commuting, and the entire life cycle of products

THE LEVERS FOR PREVENTING CO₂ EMISSIONS

Avoidance

- Global Footprint: readjusting the supply chain network

- Manufacturing Footprint: improving manufacturing processes

- Product Lifecycle: optimized product development, end-to-end

Reduce

- Energy efficiency in buildings: Green Building

- Energy efficiency in buildings: energy management

- Sourcing alternative energies, green electricity and off-grid

Compensate

- Compensation of unavoidable emissions: emissions trading, CO₂ certificates

- Corporate carbon management financing of climate protection projects

THE GREEN TRANSFORMATION CAN MAKE COMPANIES MORE EFFICIENT AND COMPETITIVE

Our team looks forward to answering your questions and supporting you on your successful path to becoming a CO₂-neutral company.

Canan Jungel

Practice Lead of SCNMSTAUFEN.AG

CURRENT AND FUTURE TRAININGS OF THIS TRAINER

III. Train-the-Trainer to become a lean trainer

Operational Excellence in SME | Albrecht Jung live

Material in flow | SEW-EURODRIVE live

II. Lean Logistics

I. Basic training as a Lean Expert

Canan Jungel was during her dual bachelor studies as an executive assistant for the international freight forwarding company Gerner + Kahle GmbH responsible for operational logistics improvements. As a master‘s degree candidate Canan Jungel contributed to the development and introduction of the Lean Logistics Seminar for Staufen Academy. Since 2014 Canan Jungel is working as an Lean Consultant and Trainer at the Staufen AG. Since then she is nationally and internationally implementing lean transformation projects with the focus for lean processes and lean logistics operations. Furthermore as a Coach she is implementing and stabilizing Shop Floor Management in various branches. Within the Staufen Academy she is responsible for trainings within the public program, internal qualification and international training standards. Besides that she designs and conducts successfully customer specific qualification and training programs.